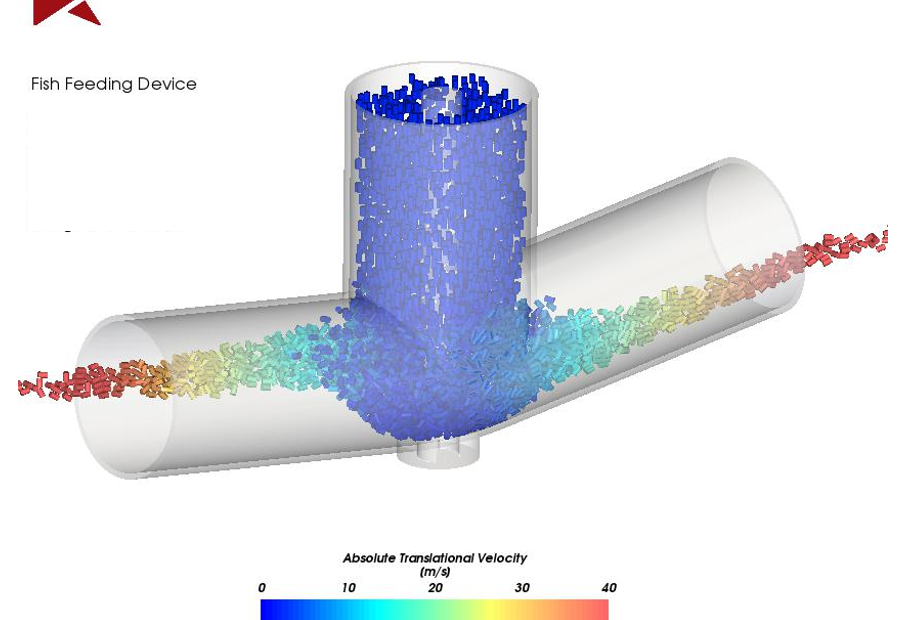

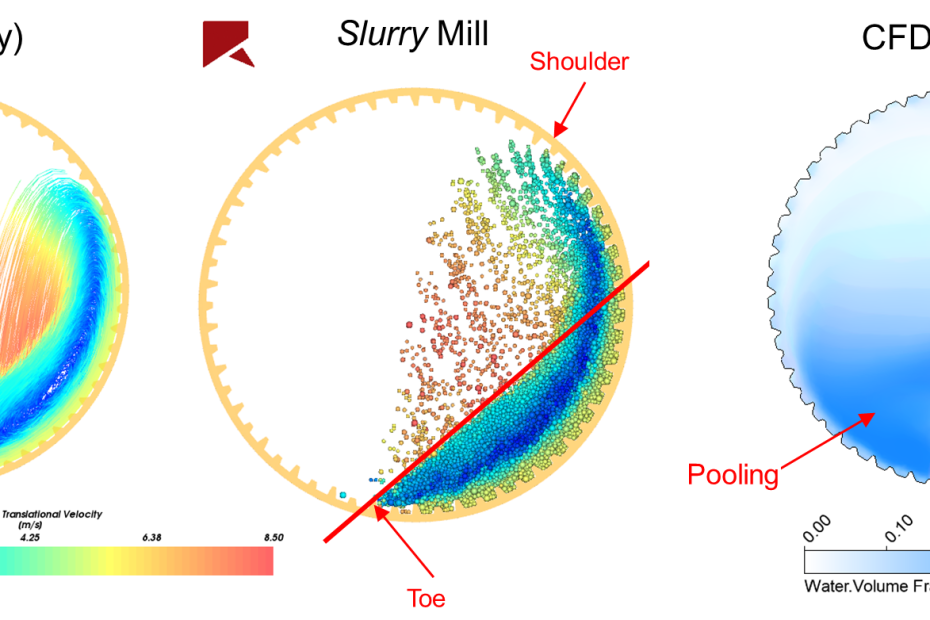

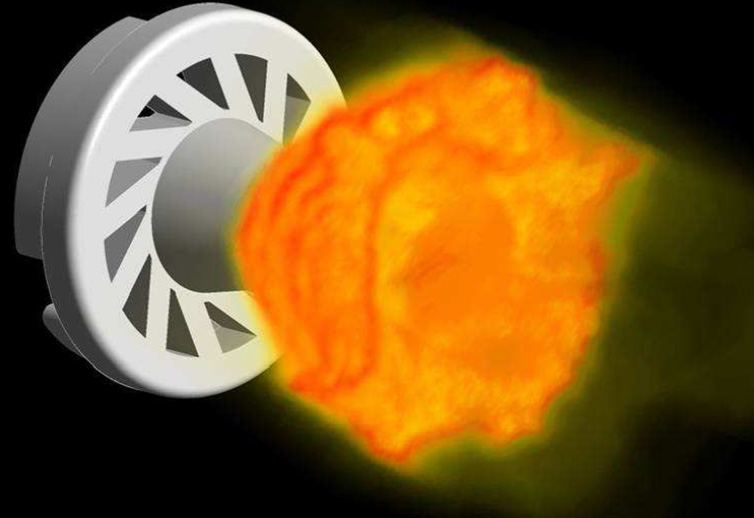

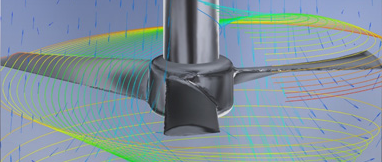

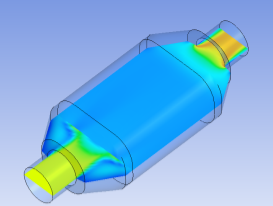

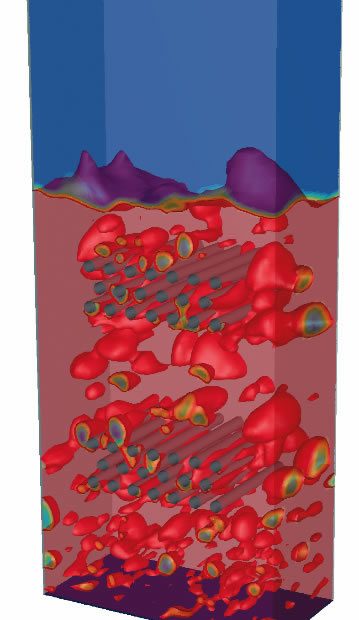

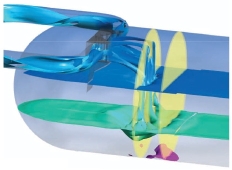

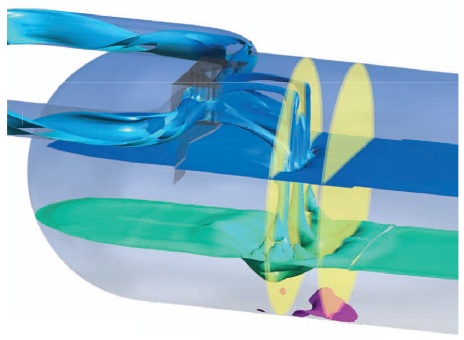

Integration of Rocky DEM + Ansys for Particle-Fluids systems

[vc_row][vc_column][vc_column_text]Rocky is a powerful, 3D DEM program that quickly and accurately simulates particle behaviour within bulk materials handling systems used across a variety of industries… Read More »Integration of Rocky DEM + Ansys for Particle-Fluids systems