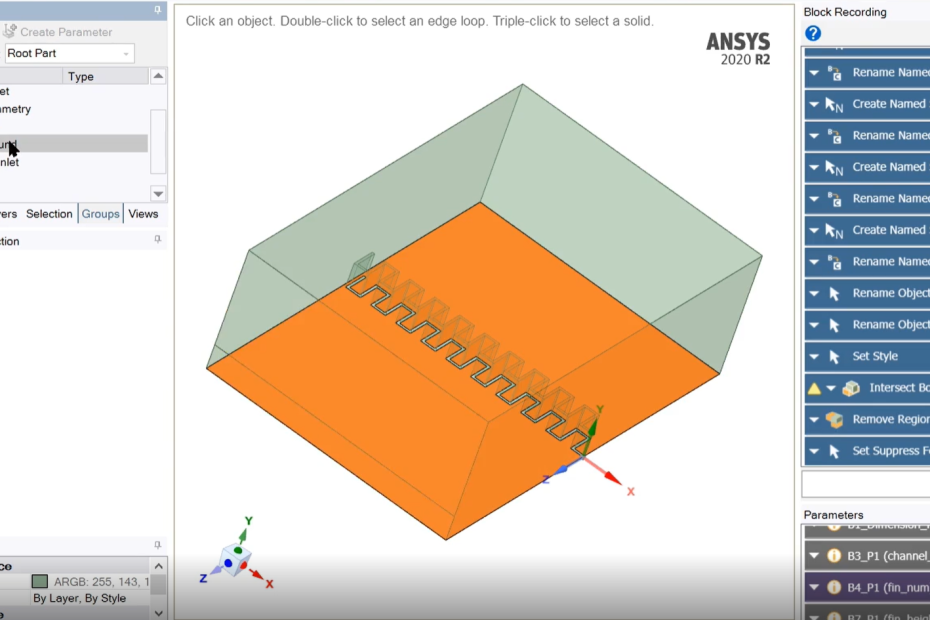

Using scripted “Record Blocks” to allow geometry parameterisation in SpaceClaim

How can CAE users make the most of the new scripting capabilities available in SpaceClaim 2020R2 to help efficiently automate the generation of new geometry designs? We look at how to create design templates that can automatically generate different designs, simply by modifying a few key parameters.