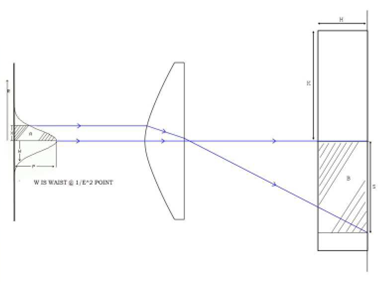

Optomechanical Design of a Tophat Beam Shaper with Ansys Zemax OpticStudio

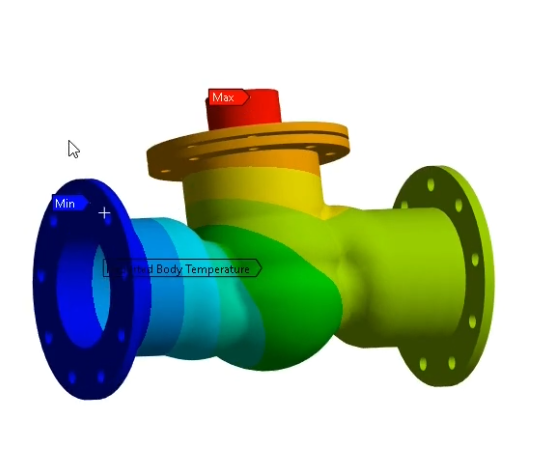

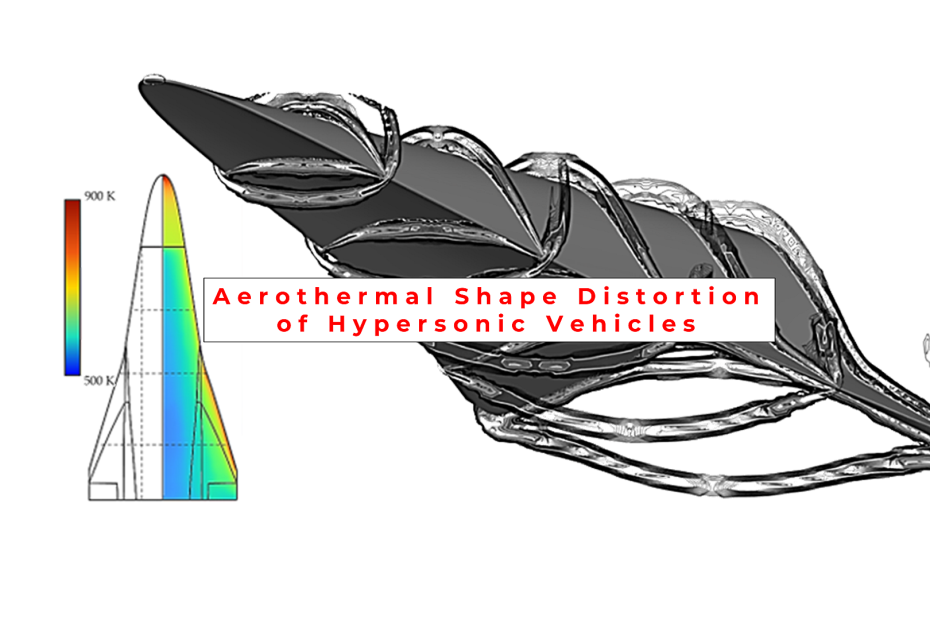

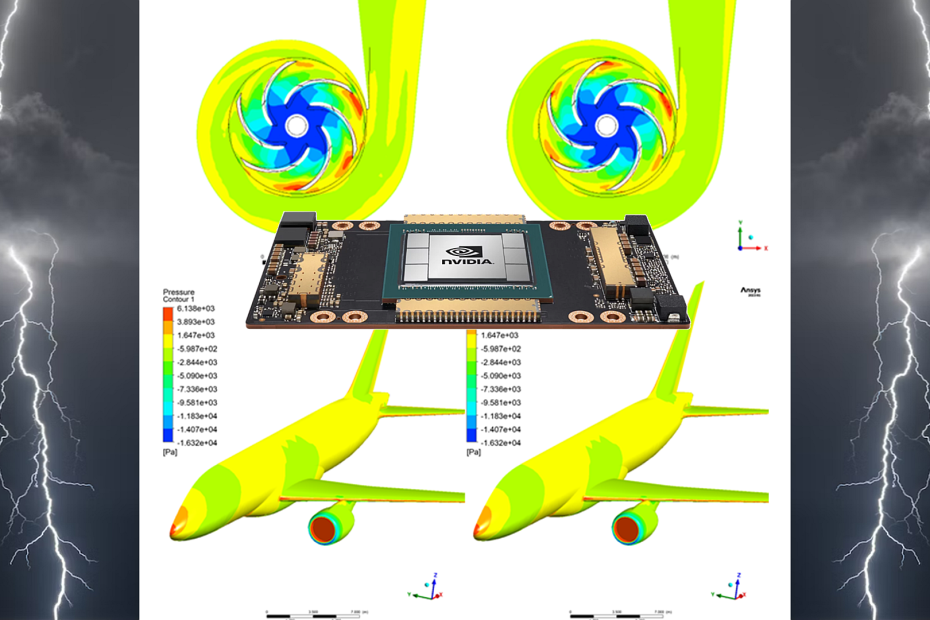

How can simulation help you to arrive at an optomechanical design that will generate the required output laser cutter beam while remaining robust under the expected thermal and structural deformations caused by the laser source?