Welding is a commonly used method that plays a crucial role in the safety, structural integrity, and durability of many fabricated structures. If a weld fails due to different modes of failures (tension, compression, bending or torsional loads), the weld will no longer be able to transfer loads between the welded components. In some cases, this may lead to the collapse of the whole structure as the weld might play a role in transferring critical load. Therefore, when designing these welds, it is vitally important to account for loading requirements, the welding process, and fatigue among other factors to prevent structural failures. Due to the geometry and the weld itself being complex, the most typical way to analyses these welds are using finite element analysis (FEA). Ansys Mechanical 2022 R1 provides a number of significant new features which greatly aide the preparation of a welded FEA model – in our experience from working on many industrial projects involving complex welded structures, these new features and capabilities in Ansys 2022 R1 will significantly reduce the model preparation time – in many cases, from a week (or more) to 1-2 days (depending on geometric complexity).

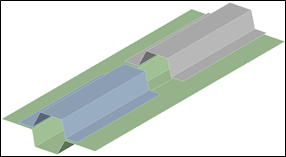

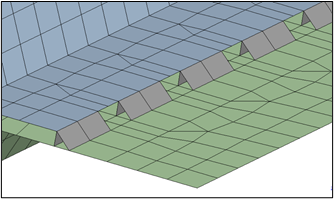

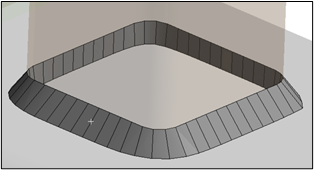

In the manufacturing process of seam welds, it is sometimes common to allow breather areas or intermittent welds. The mesh-based seam welding also supports intermittent seam welds where the user can add additional parameters to control the properties. Like with other seam welds, the user can specify if they simply want normal (extensions), angled (tents), or both. An example of intermittent seam weld is shown in Figure 1, from the input CAD to the meshed model.

Important Note: Weld creation tools are only available when using ‘Batch Connections’ – here is the link to our recent blog on the Batch Connections in Ansys.

Figure 1: Intermittent Seam Weld

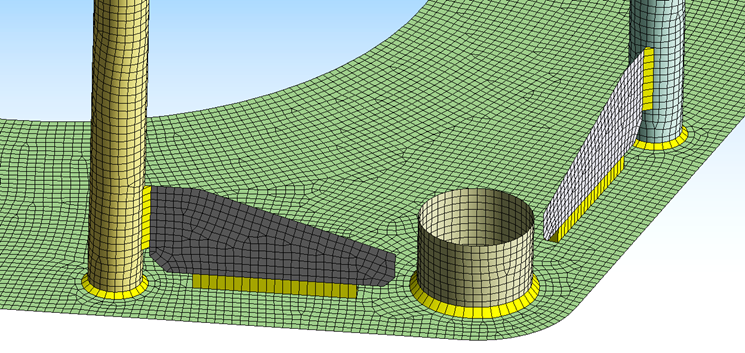

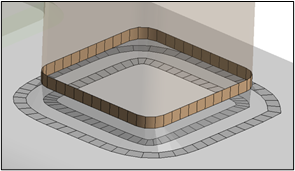

There are options to Auto-Generate Heat Affected Zone (HAZ) as a named selection for both geometry and mesh-based welds as shown in Figure 2.

Figure 2: Example of an Angled and the HAZ

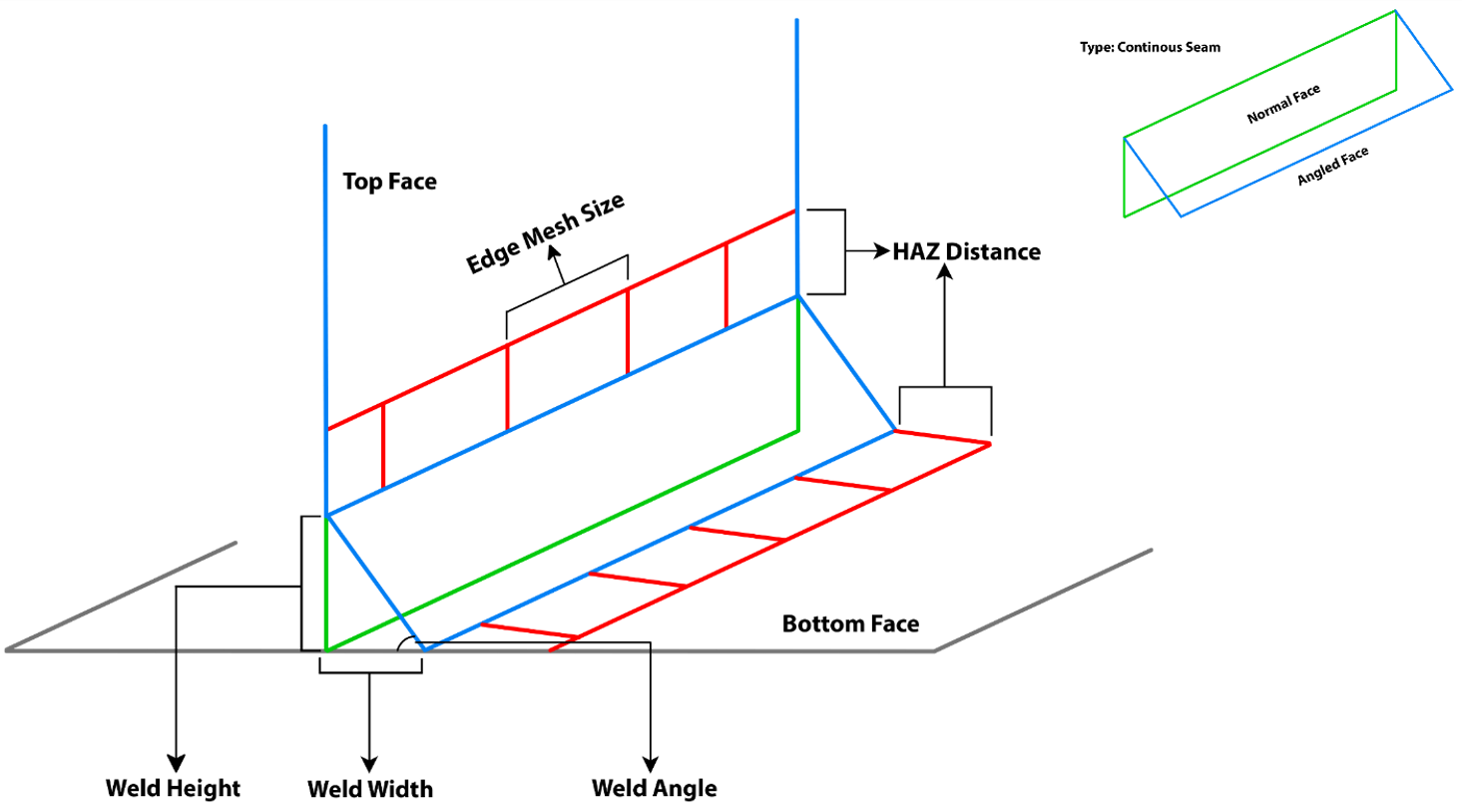

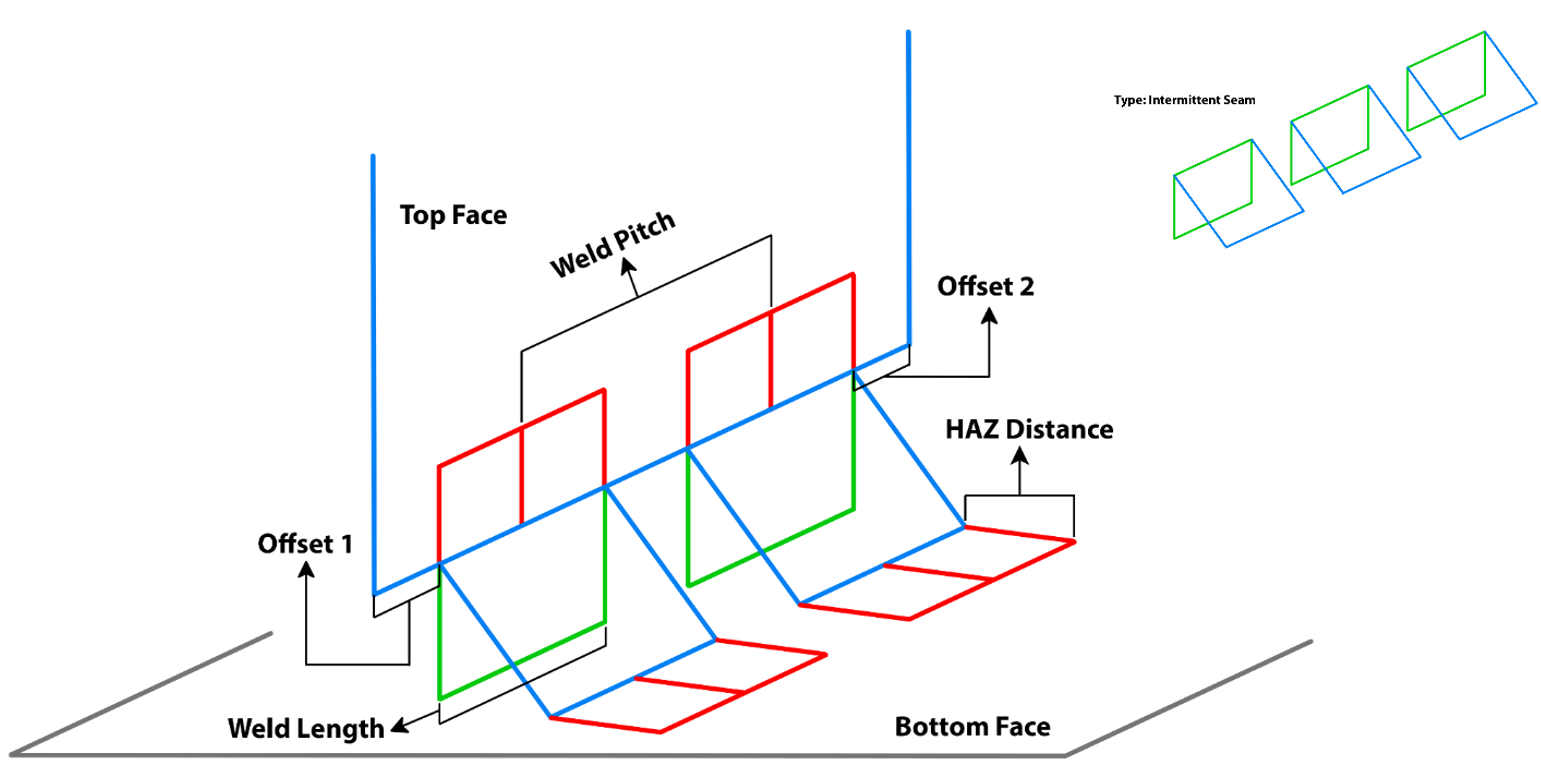

The creation of seam welds has become a lot easier in the latest release of Ansys Mechanical 2022 R1. Before we jump onto the new features, let’s define some general terminologies surrounding seam welds. Figure 3 shows the features of a continuous seam weld and Figure 4 shows the features of an intermittent seam weld.

Figure 3: Continuous Seam Weld Terminology

Figure 4: Intermittent Seam Weld Terminology

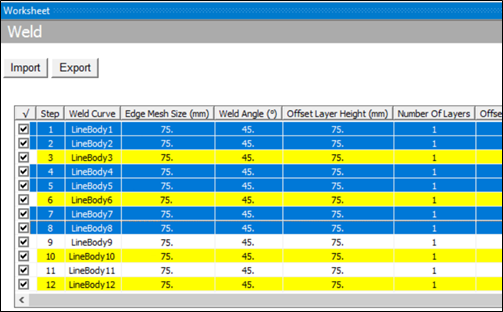

You can also work with multiple welds using worksheets as shown in Figure 5 . You can select, activate, and deactivate welds. Also, you can ‘Go to selected items in tree’ from the worksheets.

Figure 5: Worksheet Weld Objects Edit

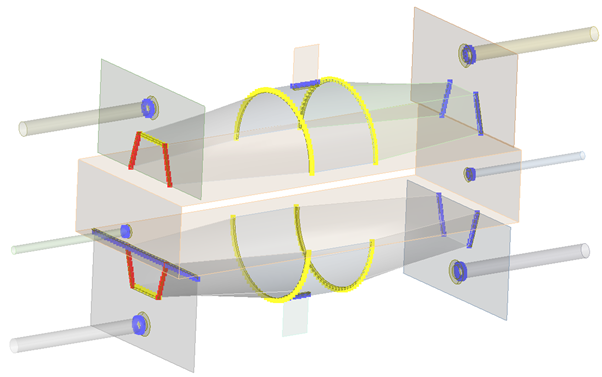

There has been a significant improvement in the way you can visualise the weld once the solve is complete. Welds are now shown in blue, yellow, and red colours to help visually identify welds based on their status (blue = passing, yellow = warning, and red = failing status) as shown in Figure 6.

Figure 6: Weld Status After Solve

For more information from LEAP’s technical team on new features in Ansys 2022 R1, check out our recent 2022 R1 Highlights blog here.