The LiveWorx 17 Technology Conference is underway this week in Boston, USA and it kicked off with a bang as PTC President and CEO, Jim Heppelman, gave the opening keynote presentation in which he outlined and demonstrated PTC’s vision for ‘true’ Product Lifecycle Management in the IoT age.

Jim provided a brief history of PTC’s journey from the originator of parametric CAD in the 1980’s to becoming the leading solutions provider today for what he describes as the ‘inevitable convergence of the physical and digital worlds’. Building on the base of PTC’s traditional technologies in CAD, PLM and ALM, Jim explains how the advent of rapid manufacturing and IoT connectivity has led to the realisation of the model-based Digital Twin. A Digital Twin is a detailed digital representation of each individual physical product in operation that is connected via IoT. For the first time, this allows for the combination of the definition of the product with the actual experience of the product.

‘By looking at this digital twin, we gain incredible insights into ways we could improve the product’s design, operation and service,’ he says, continuing, ‘with these powerful feedback loops in place for the first time, we now have the foundation for a true cradle-to-grave concept of product lifecycle management.’

With assistance from the Rexroth Bosch Group, throughout his keynote Jim took the LiveWorx audience on a journey explaining how Rexroth Bosch leverage PTC ThingWorx across their entire organisation to optimise the success of their CytroPac Hydraulic Power Unit. ThingWorx allows IoT data collected from a working CytroPac unit to be fed back to the engineering department, which helps their engineers and operations managers to both understand the in-service performance of each unit and further optimise the design of future generations.

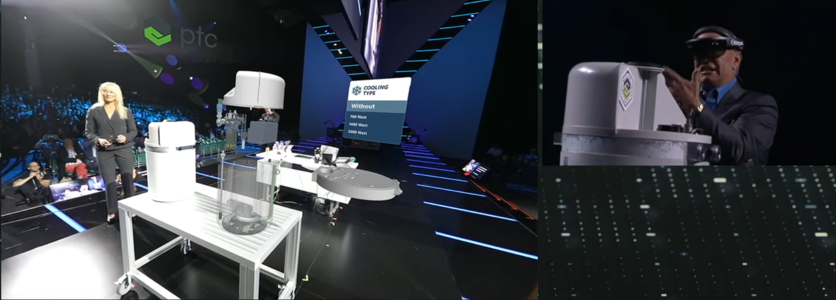

ThingWorx is also utilised by the sales and support teams at Rexroth Bosch to help to identify usage cases and potential service issues ahead of time, providing valuable insight into the customer experience and contributing to enhanced levels of customer satisfaction. The marketing team also makes use of Augmented Reality, demonstrated by Jim who showed the audience how he can select his own configuration of the CytroPak digitally while visualising it in real-time, overlayed on the real world using the Microsoft Hololens.

Finally, Jim demonstrates how ThingWorx is used to monitor a working, physical CytroPac in real-time to help factory operators gain insight into the current operational status of each unit and be instantly alerted to any potential problems ahead of time. Augmented Reality is also used here to identify any specific units requiring maintenance, with instructions shown in AR providing easy to follow steps for repair operations.

As Jim and the team from Rexroth Bosch often say, the opportunities presented by this convergence of the physical and digital worlds is truly exciting – and it’s happening right now. Whether you work in industry or academia, we encourage you to watch the video below to see the full keynote presentation (including the impressive laser light intro!) or click the links below to jump straight to the relevant section:

Introduction, PTC history and the rise of the Digital Twin: https://youtu.be/n3BP6Qnye-s?t=19m41s

Demonstration – Introduction & Engineering: https://youtu.be/n3BP6Qnye-s?t=32m9s

Demonstration – Digital Organisation for building Thingworx apps internally: https://www.youtube.com/watch?v=n3BP6Qnye-s&feature=youtu.be&t=43m36s

Demonstration: Sales & Marketing: https://youtu.be/n3BP6Qnye-s?t=51m42s (Great AR demonstration)

Demonstration: In the field: https://youtu.be/n3BP6Qnye-s?t=57m32s