RMIT Students to Gain Real-World Experience with Industrial Internet of Things (IIoT) and Augmented Reality (AR) Technologies

You may have already seen this week’s exciting announcement from PTC that RMIT University has expanded their partnership with LEAP Australia and selected the ThingWorx® IoT Platform, Windchill® software, and ThingWorx Studio technology from PTC to establish itself as an educational leader in the teaching and application of Industry 4.0 skills in Australia.

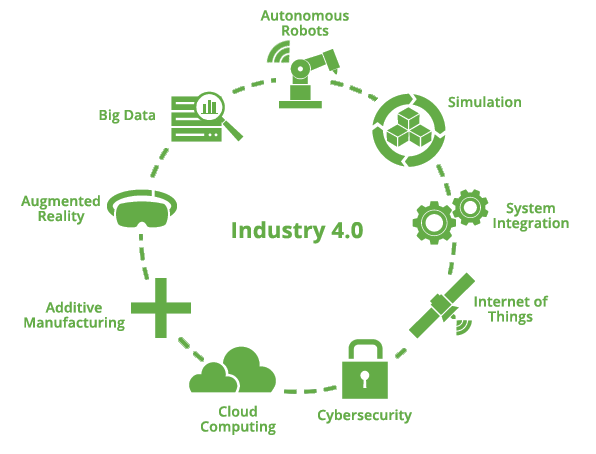

As a key member of the Australian Technology Network of universities, RMIT University has identified a recent surge in demand for graduates with skills in Industry 4.0, including the Industrial Internet of Things (IoT) and augmented reality (AR) for the enterprise. Combined with their longstanding use of simulation technology from ANSYS, RMIT University is implementing the use of PTC technology across their engineering learning and teaching (L&T) framework. In addition, industrially-driven research programs are exploring the use of PTC and ANSYS technology to combine real-time operational data from smart-connected products with robust digital prototypes to facilitate the creation of ‘digital twins’ for individual assets.

“We foresee the insights from Industrial IoT data, combined with AR for in-context display, to be critical to the business transformations that will arise from Industry 4.0 and have partnered with LEAP Australia, PTC, and ANSYS to help infuse this technology into our courses in the most effective way,” said Pier Marzocca, professor and associate dean, School of Engineering (Aerospace). “Our goal is to comprehensively expose all engineering students to state-of-the-art virtual prototyping and Industry 4.0 tools, and ensure that they acquire new employability skills and competencies that are increasingly in-demand in our extensive network of industry partners.”

In addition to deploying these technologies in a L&T context, RMIT is leveraging these new capabilities to expand its collaboration with industry partners – especially companies without sufficient in-house resources to fully realise the transformative nature of Industry 4.0 skills. Across the university, researchers are identifying the potential for companies to use real-time, real-world insights from Industrial IoT data to anticipate and address performance and maintenance issues more efficiently, and in many cases before they even occur in the field. Furthermore, they are exploring how Industrial IoT data combined with Augmented Reality (AR) provides workers with asset-specific digital information, in context, and to the right person at the right time.

Manufactured products are evolving into smart, connected devices, each embedded across broader systems and creating unprecedented amounts of data, which dramatically changes the opportunities for value creation in the economy. This transformation is radically reshaping the way companies design products and interact with customers, affecting many working roles within a manufacturing firm, and in turn, changing the educational needs of the next generation of engineers and designers.

“In discussions with RMIT, we agree that product development will shift from largely mechanical engineering to a truly interdisciplinary, systems engineering approach,” said Michael Campbell, executive vice president, ThingWorx Platform, PTC. “PTC solutions incorporating the ThingWorx IoT platform have been purpose-built to fundamentally change how we connect, analyze, manage, and experience the ‘things’ in a smart, connected world. We are proud to partner with universities such as RMIT, which require highly-capable, open, and customizable Industry 4.0 solutions that are both easy to learn and designed to be easily deployed across complex organizations.”

Here at LEAP, we are proud to formally announce this collaboration and very excited to help RMIT couple the PTC ThingWorx platform, combining Industrial IoT, PLM, and AR capabilities, with the ANSYS simulation platform that has been in use at RMIT for decades. This powerful combination will enable RMIT students and researchers to easily deploy comprehensive digital prototypes, and enable anyone within RMIT to easily analyse smart, connected products and operations, including:

- instantaneous data on current operating conditions,

- rapidly identify anomalies and diagnose operations issues,

- predict future operating and maintenance requirements, and

- improve overall product performance.

In today’s ever-changing industrial landscape, knowledge in Industrial IoT and AR and the potential of digital twin modelling is becoming an important differentiator for graduates in a competitive job market. Following in-depth discussions with our customers in industry, we have also identified that a boost in the number of graduates with Industry 4.0 skills will help to improve the competitiveness of manufacturers in Australia and New Zealand.

For more information on the technology behind Industry 4.0 and how it will impact the way you work, talk to your local LEAP office today.