Understanding slurry flows is crucial for applications such as mining and mineral processing, chemical manufacturing, wastewater treatment, agriculture and many more. Ansys Rocky DEM can help to accurately predict the behavious of a slurry by simulating the size and shape of the solid particles, the types of solids present, the viscosity of the liquid and the concentration of the solids in the liquid.

The LEAP Ansys team recently ran a webinar on the cutting-edge CFD-DEM coupling and SPH capabilities in Ansys Rocky, exploring how Rocky DEM empowers you to model slurry flows – from mills to open channels – and gain a clear understanding of particle-fluid interactions with remarkable accuracy. This article provides a summary of the webinar along with video highlights from the recording.

To kick things off, Angelo Christakakis, Application Engineer at LEAP provides an overview of the various granular-fluid systems in industry and the problems engineers face when designing them. He then goes on to explain how engineers can model these systems and outlines the ways that Rocky DEM can be coupled with Ansys Fluent to accurately represent different types of fluid-particle interactions.

In the next clip, Angelo takes a deeper dive into the various Rocky-Fluent coupling approaches and explains the differences between them, covering:

- 1-way coupling

- 2-way coupling

- Resolved, unresolved and semi-resolved coupling

- Parallelisation

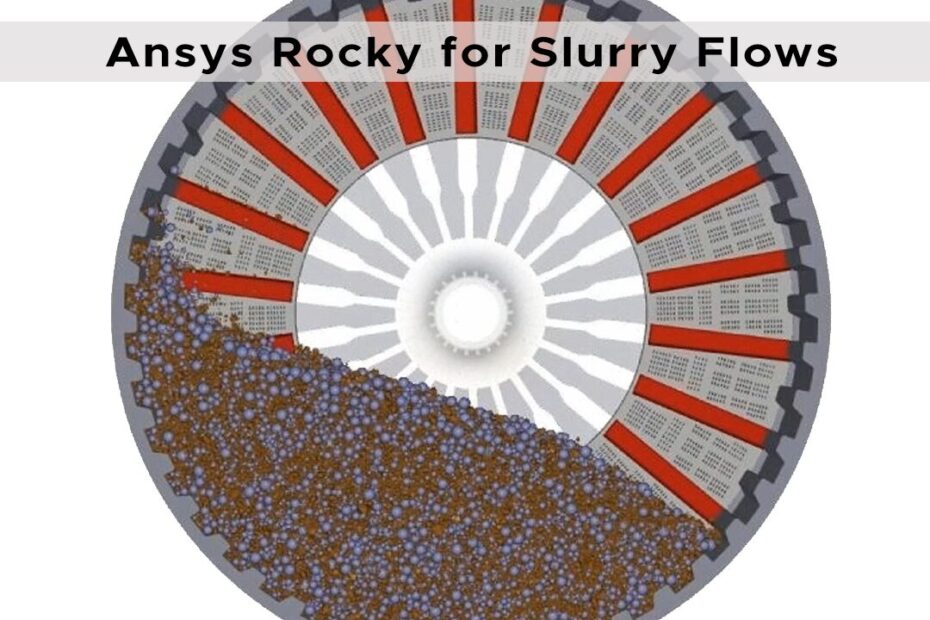

The next section covers the Smoothed Particle Hydrodynamics (SPH) approach which uses fast, meshless CFD within the DEM simulation workflow. SPH provides enhanced solutions for solid-fluid applications with free surface flows and is a particularly efficient solution for problems that include large solids. Angelo explains the pros and cons of using SPH and how it differs from the traditional CFD approach.

To finish up, Angelo provides several examples of problems ideal for using the SPH method to solve, including:

- Tank sloshing

- Tractor driving through mud

- Mixing tank

- Sticky materials

- SAG mill

Finally, Angelo details an SPH validation case undertaken on a SAG mill that compared Rocky SPH-DEM coupling results with actual experimental data, demonstrating the accuracy of the SPH method.

As always we hope that you found this article informative. If you have questions or would like further information about getting the most out of Ansys Rocky, please don’t hesitate to reach out to our technical team.