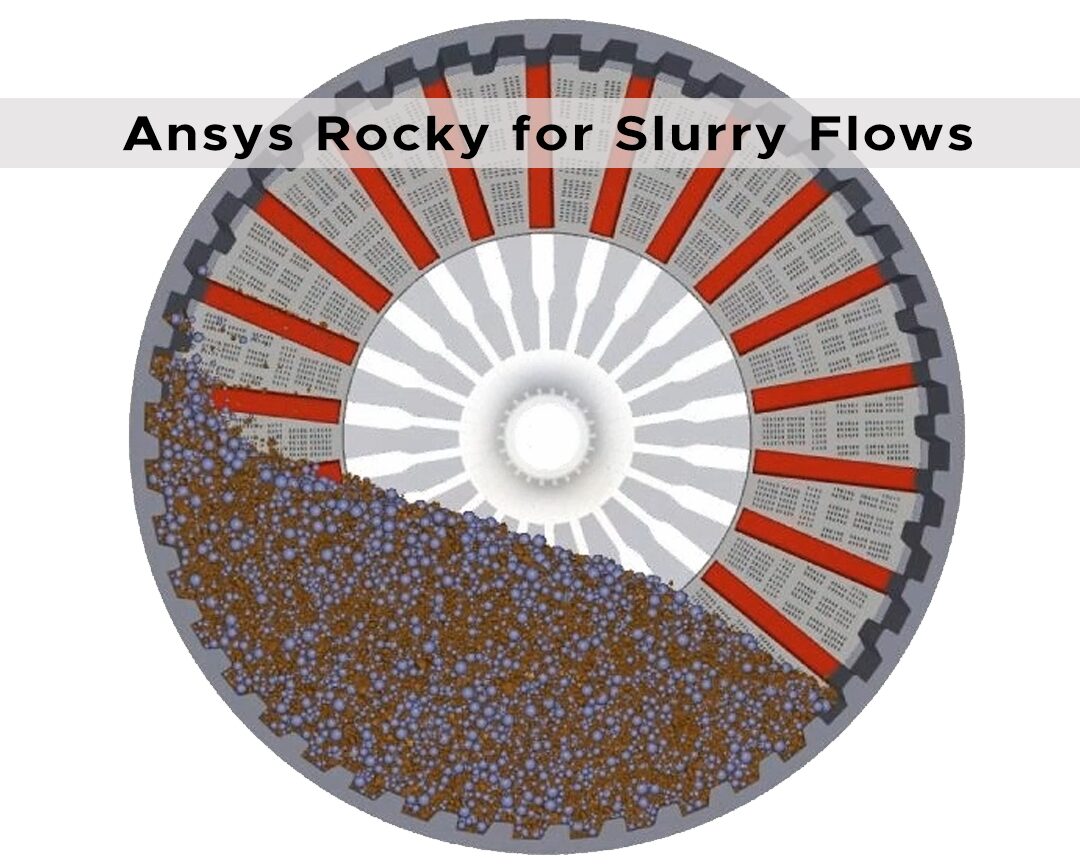

Ansys Rocky for Slurry Flows

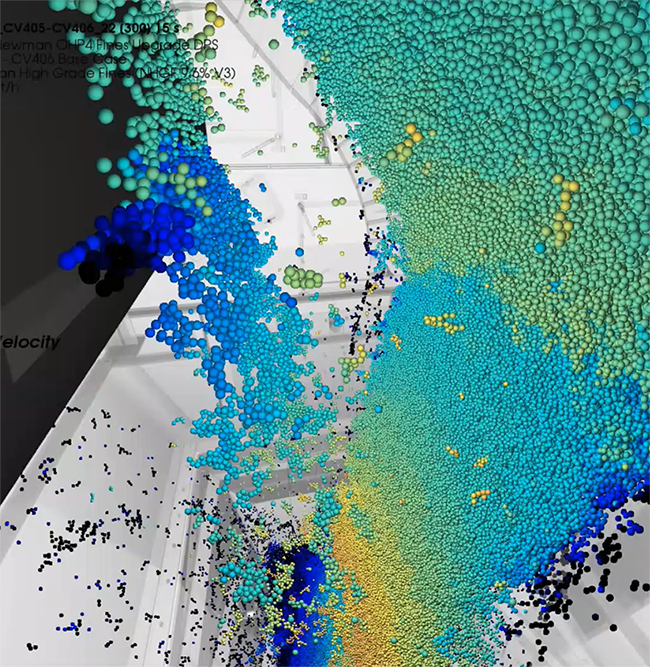

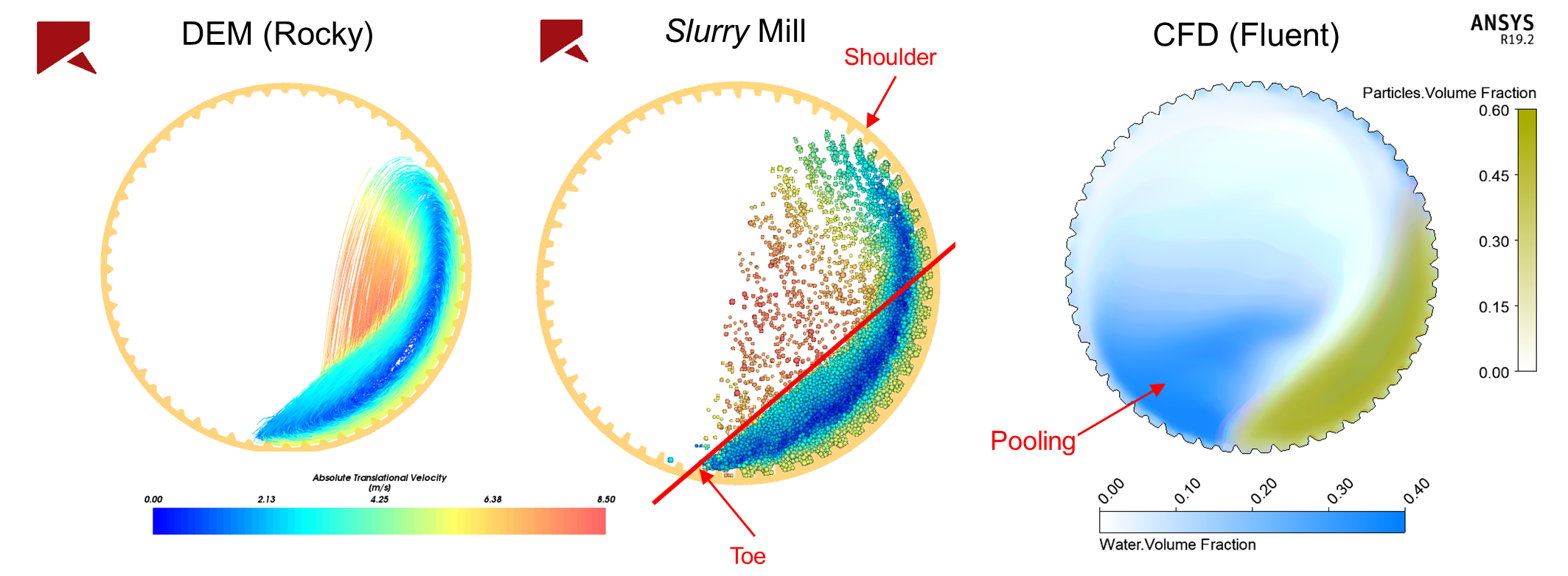

Understanding slurry flows is crucial for applications such as mining and mineral processing, chemical manufacturing, wastewater treatment, agriculture and many more. Ansys Rocky DEM can help to accurately predict the behavious of a slurry by simulating the size and shape of the solid particles, the types of solids present, the viscosity of the liquid and the concentration of the solids in the liquid.

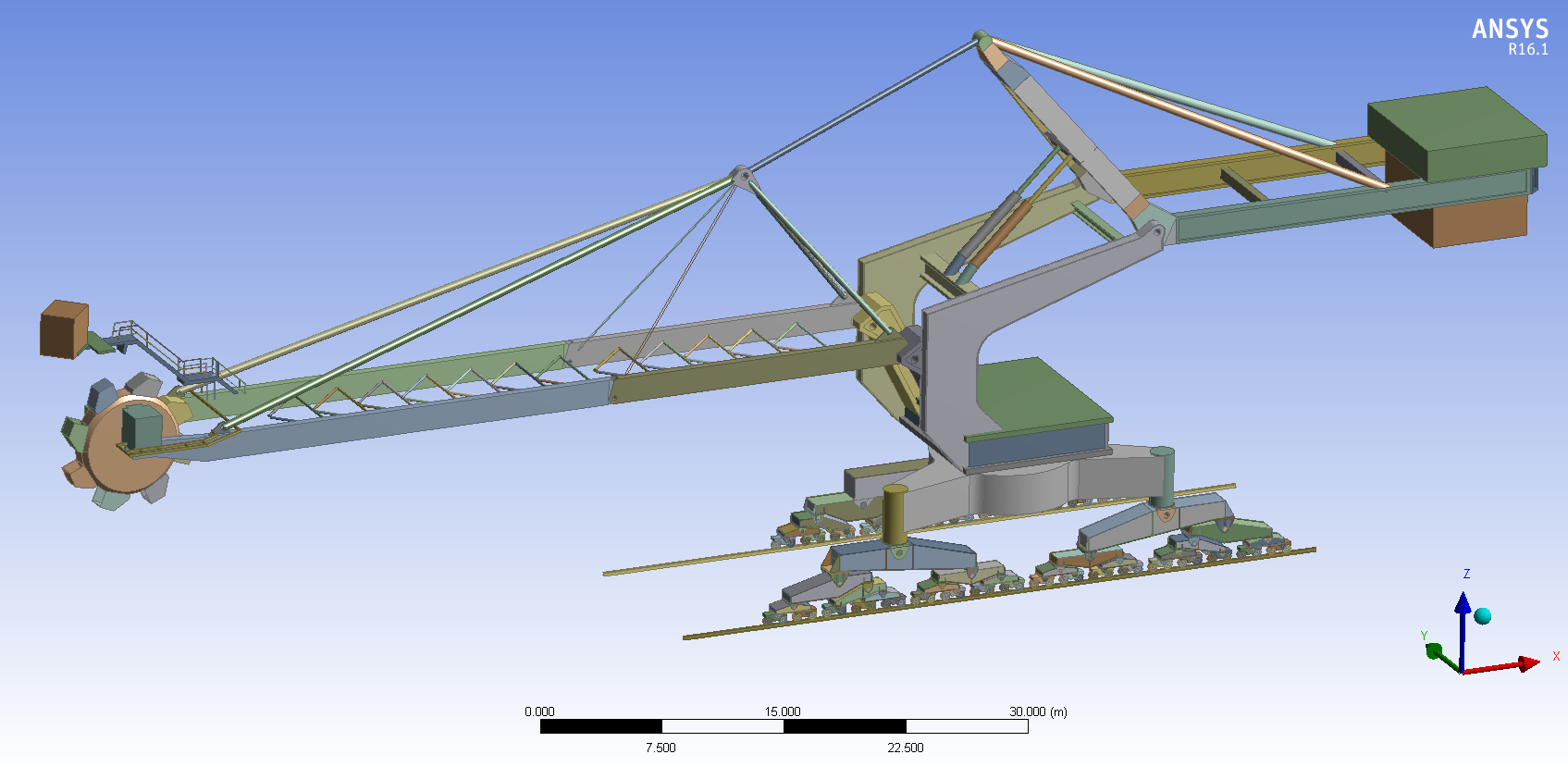

This article explains how Rocky DEM empowers you to model slurry flows – from mills to open channels – and gain a clear understanding of particle-fluid interactions with remarkable accuracy.