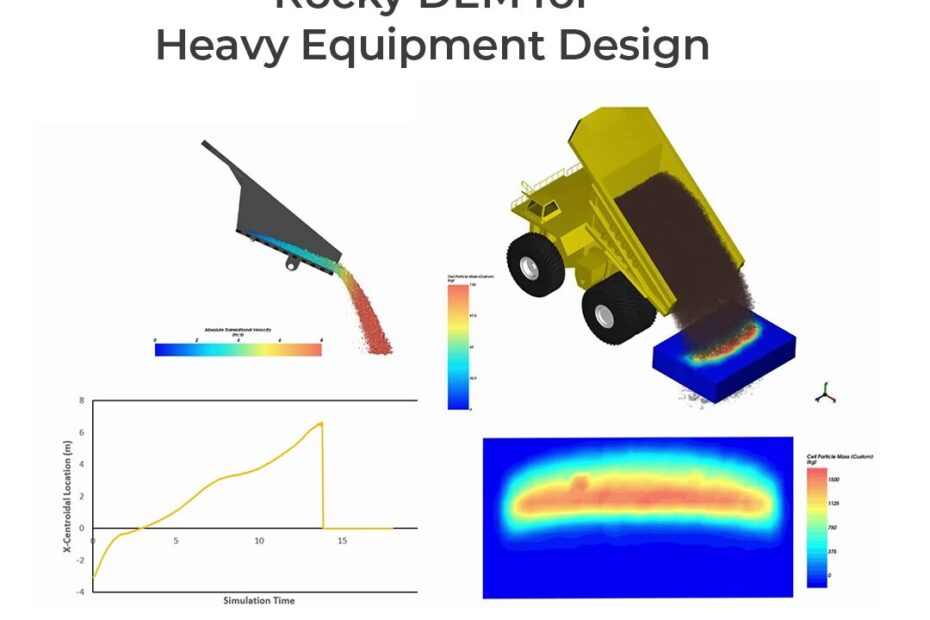

For engineers working in heavy equipment design, the ability to analyse and predict the behaviours and responses of structures in varying operating conditions is critical to ensure both safety and optimal equipment performance. At LEAP, our decades of experience with DEM has put us in the perfect position to help our customers to implement Ansys Rocky DEM, coupled with Multi-Body Dynamics (MBD) and Finite Element Analysis (FEA) solvers.

Ansys Rocky is a powerful, 3D Discrete Element Method (DEM) solver that quickly and accurately simulates particle behaviour within systems of bulk materials. Bulk materials are ubiquitous globally across a wide variety of industries, such as mining and minerals processing, through to food, pharmaceutical, and agriculture. The extensive range of capabilities of Ansys Rocky software has allowed for engineers across Australia and New Zealand to gain insights into many types of particles and bulk materials handling systems.

Coupling Rocky DEM with Ansys Mechanical provides design engineers with a greater detailed understanding of the structural response of your heavy equipment, while transporting, storing, or otherwise processing bulk materials. While Rocky evaluates particulate behaviours, trajectories and interactions, Ansys Mechanical’s structural solver predicts the determination of deformations and subsequent stresses experienced by the structure, due to interactions with the bulk material. Engineers are then able to understand the severity of various different loading conditions, providing a means to troubleshoot and optimise their designs.

The critical advantage of this workflow is that instead of engineers being forced to make assumptions regarding their loading conditions, which may be inaccurate, conservative of invalid in some cases, they are able to use loading data based on explicitly resolved contact loads between the bulk and surrounding structure, allowing your simulation to better represent what happens in reality.

Recently LEAP ran a webinar where Angelo Christakakis, Application Engineer at LEAP, discussed the various ways that Ansys Rocky can be combined with other tools within the Ansys product portfolio, to deliver higher fidelity simulations – with a focus on the heavy equipment industry. The presentation had a particular focus on ground engaging equipment, trucks, and trays, but many of these features and capabilities discussed also extend to other industrial applications. In this blog, we have summarised Angelo’s presentation and provided the video highlights. So, are you ready to elevate your design and analysis capabilities of heavy equipment with Ansys Rocky? Explore further by watching the videos below.

To begin, Angelo provides an overview of Rocky and the Discrete Element Method, and how and why DEM solvers are used within industry.

Next, we take a deeper dive into some simulation basics, outlining the process of including geometry motions into the model, as well as illustrating some post-processing capabilities.

Moving on, the benefits of coupling Rocky with Ansys Mechanical are outlined, including the automated coupling through the Workbench platform. Similarly, the topic of modelling the abrasive wear/erosion of geometries is briefly introduced, with a showcase of the implementation of an explicit wear model within Rocky.

Following, the concept of a DEM-FEA analysis is explored in further detail, with an overview of some of the important considerations that need to be made when setting up an analysis of this type in Rocky. A modified workflow, which is used to couple the result of a Rocky standalone result with Ansys Mechanical is included in the demonstration.

Finally, Angelo explains how the capabilities of Ansys Rocky can again be furthered, this time through a coupling with Ansys’ multi-body dynamics solver – Ansys Motion. Here, not only can the realistic motion of geometries be modelled in the DEM solver, but control systems for the motions can be introduced.

Have you faced challenges in simulating particle behaviour in your projects involving heavy equipment design? If you would like more information on Ansys Rocky and how DEM can extend your in-house analysis and design capabilities, please do not hesitate to contact us to discuss your next project.