Following from Part 1 in our series on how to use reliability physics analysis (RPA) tools to help meet important industry standards, today we look at the MIL-810G standard which is a collection of environmental engineering considerations and laboratory tests approved for use by all Departments and Agencies of the Department of Defence (DoD) in the United States. MIL-STD-810G consolidates the basic -810F and it also includes a number of corrections, significant changes and includes new test methods. Although prepared specifically for DoD applications, this standard may be tailored for commercial applications as well.

The standard is structured in three Parts.

Part I describes management, engineering and technical roles of test tailoring process.

Part II contains the laboratory tests methods to be applied to the general and specific test tailoring guidelines in Part One. The tailoring options vary across the different tests, but the standard provides background rationale that guides engineers through the tailoring process.

Part III refers to various sources providing climatic data and guidance. It helps to find the most appropriate climatic conditions for R&D, virtual prototyping via CEA and test.

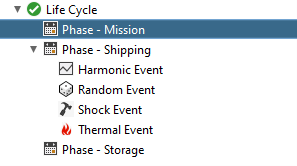

Fig 1: defined phases of military hardware in Ansys Sherlock. Different Events can be associated to each Phase and then analysed independently or combined to predict probability of failure.

The standard gives also clear life cycle histories of military hardware which include the shipping, the storage (logistics) and the mission scenario. You can define the same phases in the Ansys Reliability Physics Analysis (RPA) tools specifying the different load cases under each event the hardware will see.

What tests can be specifically replicated inside the Ansys RPA testbench?

There is a number of tests that can directly be reproduced inside Ansys Sherlock according to correct load conditions for your designed hardware. The following Table 1 shows applicable laboratory test methods.

Tab. 1: Relevant sections of standards addressed by Sherlock RPA Tool.

| No. | Title | Pages | No. of pages |

| 501 | High Temperature | 501.5-1 – 501.5-13 | 13 |

| 502 | Low Temperature | 502.5-1 – 502.5-9 | 9 |

| 503 | Temperature Shock | 503.5-1 – 503.5-13 | 13 |

| 513 | Acceleration | 513.6-1– 513.6A-6 | 19 |

| 514 | Vibration | 514.6-i – 514.6E-8 | 93 |

| 515 | Acoustic Noise | 515.6-1 – 515.6B-2 | 15 |

| 516 | Shock | 516.6-i – 516.6C-4 | 59 |

| 517 | Pyroshock | 517.1-i – 517.1-24 | 26 |

| 519 | Gunfire Shock | 519.6-i – 519.6E-7 | 83 |

| 520 | Temperature, Humidity, Vibration, and Altitude | 520.3-i – 520.3-22 | 24 |

| 521 | Icing/Freezing Rain | 521.3-1 – 521.3-7 | 7 |

| 522 | Ballistic Shock | 522.1-1 – 522.1-14 | 14 |

| 523 | Vibro-Acoustic/Temperature | 523.3-i – 523.3A-9 | 28 |

| 524 | Freeze-Thaw | 524-1 – 524-6 | 6 |

| 525 | Time Waveform Replication | 525-i – 525B-11 | 57 |

| 526 | Rail Impact | 526-1 – 526-7 | 7 |

| 527 | Multi-Exciter Testing | 527-i – 527D-3 | 37 |

| 528 | Mechanical Vibrations of Shipboard Materiel | 528-i – 528B-3 | 27 |

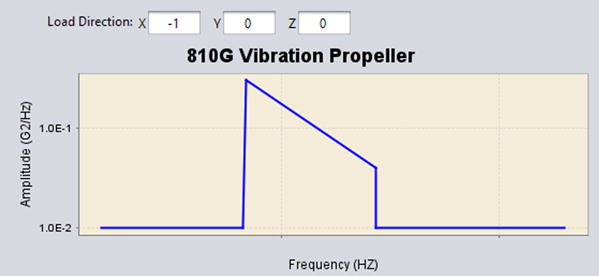

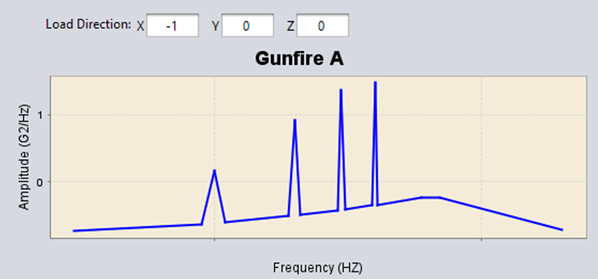

Following are two examples of load profiles for random vibration inside Sherlock’s Random Vibe Editor.

Fig 2: Load profile in Sherlock’s Random Vibe Editor defining a Gunfire load for 20mm 100rounds/sed with a 1,500 Round magazine.

Fig 3: Test Vibration for a Category 13 Propeller inside Vibe Editor

More examples for Gunfire, Missile Storage, Rotary Wing vibrations as well of temperature cycles for Cold and Hot/Dry environment are available.

Ansys and LEAP provide a complete workflow for the electronics manufacturers in defence, which allows engineers & designers to determine how long it takes for a product to fail and why the failure has occurred.

Sherlock’s ability to model components with a high level of detail provided more accurate results and its lifetime predictions are based on physics of failure and can be used to comply electronic circuit boards for various reliability standards. This is the final in our multi-part blog series on Ansys Reliability Physics Analysis tools and how Ansys Sherlock can be applied to address standards such as SAE J3168, GMW3172, DO-160G & MIL-810G across different sectors.