Augmented reality (AR) is generating much excitement amongst technology enthusiasts worldwide, but it is also worth considering how AR may disrupt the way companies do business by enabling engineers, technicians and consumers to experience their products in a completely new way.

Historically, it has been challenging for manufacturers to develop and deploy AR if they did not have access to a team of skilled coders and a sizeable budget – fortunately, recent hardware advances and ongoing software development by companies such as PTC have meant that AR has never been more accessible to engineers and designers within the industrial enterprise.

So what is Augmented Reality (AR) exactly?

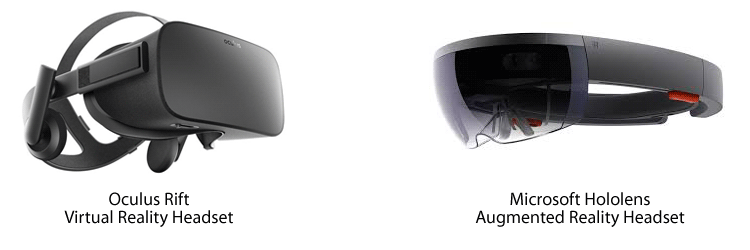

AR is often confused with Virtual Reality (VR) – the clear distinction is that while VR completely immerses the user inside a virtual world using a headset, AR instead projects a digital/virtual overlay on top of the user’s view of the real world (using either a headset or a tablet/phone). Unlike in VR, when using AR you are rarely in danger of unknowingly bumping into your colleagues or being run over by a forklift!

What equipment do I need for AR?

In recent years, the hardware technology that enables AR has developed very rapidly: Microsoft Hololens is among a number of AR goggles being released to the market, and consumer tablets and phones have become more powerful and less expensive, allowing anyone to experience AR for ourselves (just think about the phenomenon that was Pokemon Go in 2016!). The accessibility of these powerful & portable computing devices has prompted industry to begin exploring ways in which AR technology can be used to gain a competitive advantage.

The earliest examples of AR experiences brought to market have been in sales and marketing: commonly used to display products virtually when the physical version is not present, such as:

– visualising the position and scale of new furniture in a room – such as the AR-enabled IKEA catalogue

– allowing consumers to explore and interact with products prior to purchase – such as the interactive LEGO catalogue

Now many more companies involved in product development have awoken to the full potential of AR – and we foresee rapid changes in how future smart, connected products will be designed, manufactured, monitored and maintained.

What tools do I need?

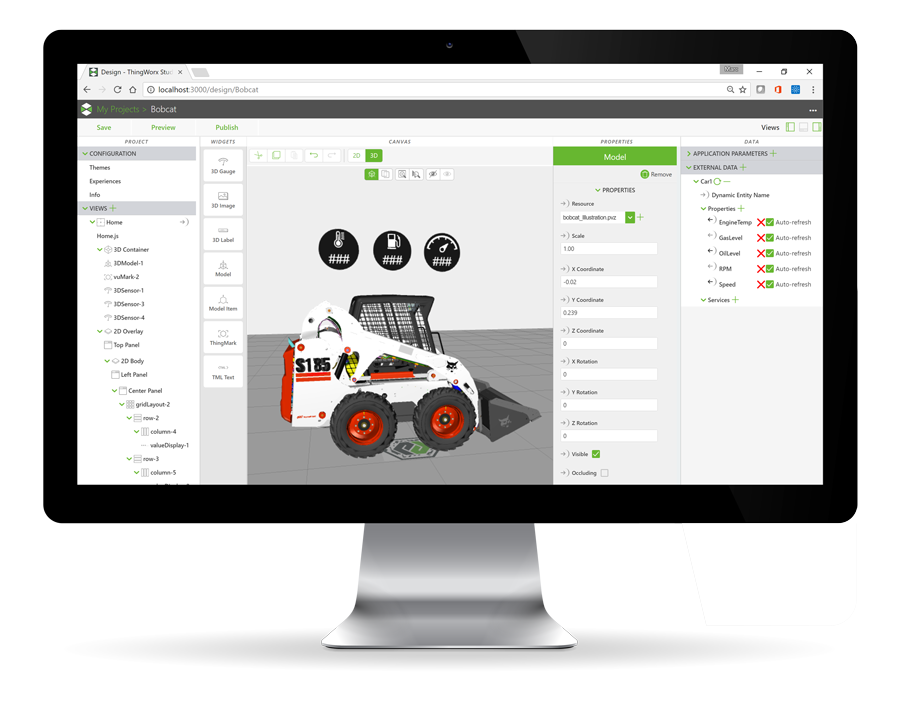

Fortunately, PTC correctly identified the likely impacts from the industry 4.0 revolution many years ago: they have been busy revamping their product line-up for over 5 years to accommodate these rapidly emerging trends towards smart, connected products. What is key for manufacturers in creating and servicing smart, connected products? IoT and AR! To round-out their existing technology in 3D CAD modelling and product lifecycle management (PLM), PTC has acquired best-in-class technology in Thingworx (IoT platform) and Vuforia (AR) – and pulled out all stops to integrate these tools and achieve their ultimate goal of bridging the gap between the physical and digital worlds.

For existing Creo 4.0 customers, PTC has made it incredibly simple to take your existing CAD models and publish detailed and impressive AR experiences – it could be argued that it is now just as easy to publish your CAD model to AR as it is to publish a traditional drawing. If your company requires more interactive AR experiences, you can also leveraging existing documentation tools such as Creo Illustrate (and utilise the same content you’ve already created to build your traditional product documentation, to publish animated AR sequences). This effectively means that most typical 3D CAD users in industry are already 99% of the way to creating useful AR experiences.

In industry, AR has significant implications for how these smart, connected products can be monitored and serviced in the field. For example, as demonstrated in the video below, a service technician can utilise an AR virtual manual that allows for visual inspection and instruction of a product in real time – and be presented with a step-by-step process to resolve it. This obviously eliminates the need for traditional manuals and, importantly, allows for remote assistance from a more experienced technician when required. The possibilities are significant for a country like Australia – with businesses attempting to provide coverage across such vast distances! Imagine yourself as the maintenance manager in a remote mining site in Western Australia, struggling to manage the training requirements for a team of semi-skilled service technicians. Instead of needing to fly-in “expert” technicians (with a lead time of at least 12-24 hours), his team can now be trained ‘on demand’ on-site to service any unfamiliar equipment they encounter.

When combined with IoT connectivity delivering real time product performance data, AR also provides valuable insights into what is going on ‘under the hood’ of your product. This is particularly useful for products that do not have a physical interface as AR can provide this data in place of dials or screens.

We are excited by recent developments which have seen high-profile companies (such as Apple and Google) making a strong push into AR – we see that this will only accelerate the development of AR technology and raise awareness at the consumer level. In turn, more engineers and product designers will realise how AR can be used outside within the industrial enterprise.