[vc_row][vc_column][vc_column_text]As your train rumbles along during your morning commute, you are more likely to be hooked to your smartphone than thinking of all the types of simulations that have gone into making your journey safer and provided a more comfortable ride (though unfortunately they still can’t help with that odour coming from one of your riding companions!).

Engineers working in the rail industry will recognise the expanding use cases of FE and Emag simulations that are now undertaken on a routine basis in the development of new systems: from the design of individual components, sensors and actuators, to fatigue of structural members and critical components such as wheels, axles, bogies; through to the creation and certification of safety-critical software code: engineering simulation tools are now used comprehensively throughout the rail industry.

Let’s take a journey through a range of recent examples to learn more:[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_single_image image=”1445″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Multiphysics simulations avoid thermal cracking in diesel engine cylinder heads:

Ural Diesel-Motor Works builds diesel engines used in marine and railroad applications ranging from 1,050 HP to 2,600 HP. When the company found that their engines were experiencing periodic problems with the aluminium cylinder heads, they turned to multiphysics simulation to investigate them. Cracks appeared in the cylinder head near the injector, and water leaked from the cooling jacket into the space between the head and injector. In extreme cases, the water mixed with fuel, causing the engine to stop running.

Multiphysics simulations that involved fluid, thermal and structural influences to predict fatigue were used as an efficient way to thoroughly examine the range of conditions and ensure reliability.

Read more here.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_single_image image=”1451″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Dealing with EMI/EMC in Power Electronics for Railway Applications

The electric drive is the heart of nearly every modern train. Controlling high power densities allows for efficient and fast movement. Over the last decade power electronics components have taken a huge step forward with the ability to deal with higher voltages, operating in overall greater packaging densities and favour with much faster switching. However with these new advancements come new engineering challenges such as thermal considerations, insulation fatigue, bearing currents and the constant need to monitor losses.

But all those issues are relatively small when compared to electromagnetic compatibility, by far the most important consideration on the development roadmap with the need for significant investment in both cost and man hours. The ultimate goal is to reduce higher radiating content that may potentially interfere with nearby communication electronics and even more importantly, passengers.

We at LEAP understand these challenges and provide industry leading workflows for EMC considerations in power electronics systems, from the very beginning of the development process.

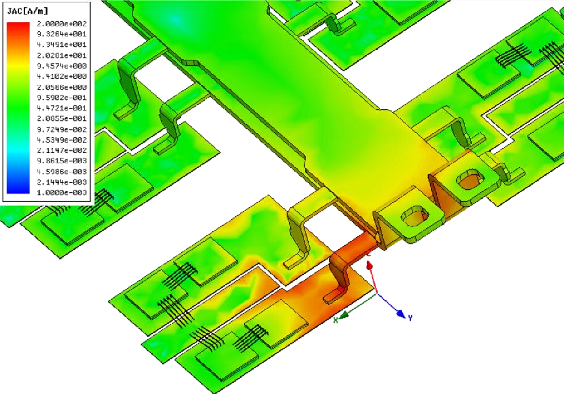

At the core of our advanced EMC modelling practices is the efficient insourcing of fully dynamic semiconductor models combined with the full coverage of parasitics in the electronics.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_single_image image=”1446″ img_size=”full” alignment=”center”][/vc_column][vc_column width=”1/2″][vc_single_image image=”1447″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Fig.1: Possible and nowadays a standard in EMC simulations with ANSYS: Extracting the parasitic effects from a 3D package geometry

That high fidelity simulation model puts the engineer in a position to develop a cost effective virtual EMC design process and run first-pass EMI testing as early as possible, when the physical prototype is still up in the anechoic chamber.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_single_image image=”1448″ img_size=”full” alignment=”center”][/vc_column][vc_column width=”1/2″][vc_single_image image=”1449″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Fig.2: Dynamic IGBT and MOSFET components accurately capture the switching waveforms which makes them suitable for an EMI/EMC analysis

Worldwide Industry leaders like GE, ABB and Siemens are using those workflows to overcome EMC challenges. Hear from a rail engineer at ALSTOM on his experiences in using ANSYS to design power electronics for railway applications:

“Today, trains have to be beautiful and there is the matter of space where you can put electronics. Some questions from the customer are: how can you make me forget about electronics inside my trains? We give innovative integrated technologies to put power electronics everywhere we can in very tiny, tiny spaces. That’s how we work.

We simulate with ANSYS tools the use cases, the way we use the product, the way the customer will use the product. Then, we check does it reach the performance or not. “

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text][/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]For signaling engineers, ANSYS SCADE ensures your interlocking systems will:

- work the first time

- avoid budget overruns

- guarantee work done within the delivery schedule

SCADE offers:

- Automated development for seamless mapping between software Architecture, Design and Coding.

- Automated test and validation

- Fully Automated Documentation

- Safety certification to EN50128 (see more detail below)

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text][/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

SCADE provides certification for EN 50128 up to SIL 3/4

Esterel Technologies has developed a unique EN 50128 Methodology Handbook, now available here for download, which includes development and verification steps and design guidelines for developing efficient models and generating efficient code, such as:

- Model-based development with SCADE

- Model and Code optimization

- Timing & Stack Optimization

- Simulation and Model Test Coverage, and formal verification

These are just a small taste of how FEA, Emag and Software Certification tools are increasingly being used by engineers and designers across the rail industry. Contact LEAP today if you have specific requirements that you’d like to discuss, or visit us at Ausrail 2017 in Brisbane from Nov 21-23 – click here to arrange a meeting with our engineers on stand 718.[/vc_column_text][/vc_column][/vc_row]